SUZHOU, JIANGSU, CHINA, January 27, 2026 /EINPresswire.com/ — The global manufacturing landscape is currently undergoing a decisive paradigm shift. For decades, the industry focused on isolated automation—replacing manual labor with programmed machinery. However, today’s challenges, characterized by fragmented supply chains, volatile market demands, and the urgent need for decarbonization, require a more integrated approach. The modern competitive edge no longer rests on individual machines but on systemic integration capability. Amidst this transition, CCIG has emerged as a China Top Intelligent Automation Platform Factory, leveraging its unique mfgWorld ecosystem to bridge the gap between disconnected manufacturing silos and creating a unified, responsive production environment.

Five Defining Trends Shaping the Smart Factory of Tomorrow

As manufacturing enters a new era of integration, five critical trends are emerging that will fundamentally reshape production environments over the next decade.

Human-Machine Collaboration is evolving beyond simple automation. Advanced cobots now work alongside human operators in shared workspaces, leveraging AI to adapt to varying production rhythms and worker expertise levels. This symbiosis maximizes both precision and flexibility.

Supply Chain Transparency has become non-negotiable. Real-time visibility across multi-tier supplier networks enables manufacturers to anticipate disruptions, verify component provenance, and ensure ethical sourcing—critical capabilities in an era of regulatory scrutiny and consumer awareness.

Real-Time Carbon Footprint Tracking transforms sustainability from compliance obligation to competitive advantage. Smart factories now monitor energy consumption at the machine level, optimize production schedules to leverage renewable energy peaks, and provide verifiable emissions data to stakeholders.

Distributed Manufacturing Networks replace monolithic production facilities. Cloud-connected micro-factories positioned near end markets reduce logistics costs and carbon emissions while maintaining quality consistency through standardized digital processes.

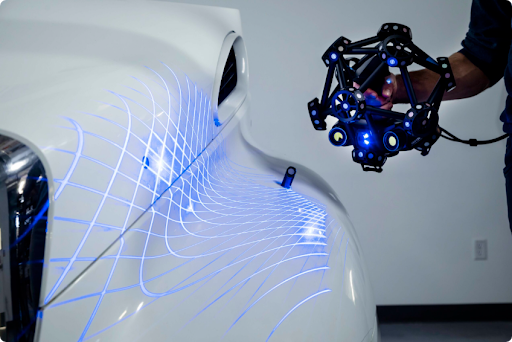

Digital Twin Technology has matured from simulation tool to operational necessity. Virtual replicas of production lines enable risk-free testing of process changes, predictive maintenance, and rapid troubleshooting—reducing downtime and accelerating continuous improvement cycles.

These trends converge on a single requirement: the ability to orchestrate complex, geographically dispersed assets through unified digital platforms—precisely the capability that defines platform-based manufacturing enterprises like CCIG.”

The Three-Dimensional Architecture of Intelligent Manufacturing

To understand the future of the smart factory, one must analyze the integration of physical flexibility, digital orchestration, and institutional reliability. CCIG, established in 2016 through a mixed-ownership structure involving CRRC and strategic investors in the Yangtze River Delta, has built a model that addresses these three critical dimensions.

At the physical level, the hallmark of a smart factory is “Hardware Flexibility.” Traditional production lines are often rigid, requiring significant downtime for retooling. CCIG addresses this through its advanced manufacturing philosophy, utilizing fully integrated process chains such as the Salvagnini flexible sheet metal systems. By synchronizing punching, shearing, laser cutting, and bending within a single, autonomous workflow, the factory achieves a level of physical agility that allows for near-instantaneous switching between different product specifications. This hardware layer is designed to be “future-proof,” accommodating the rapid iteration cycles common in high-tech sectors like new energy vehicles and precision electronics.

Moving to the data layer, the orchestration of these physical assets is managed via the mfgWorld platform. This is where “Management Cloudification” takes place. By utilizing the industrial internet, CCIG connects its sprawling network of manufacturing bases—spanning the Yangtze River Delta, Pearl River Delta, and Central China, to international hubs in Hungary and Malaysia—into a singular, transparent resource grid. This cloud-based architecture enables real-time monitoring of production metrics and dynamic resource allocation. When a demand surge occurs in one region, the platform can redistribute workloads across the global network, ensuring that production remains optimized regardless of local disruptions. This shift from local control to global orchestration is the defining characteristic of a platform-based manufacturing enterprise.

Finally, the “Endorsement Layer” provides the necessary certainty for high-barrier industrial projects. Manufacturing at scale requires significant capital and technical depth. With total assets of nearly 50 billion yuan and net assets exceeding 28 billion yuan, CCIG possesses the financial stability required to support multi-year industrial transformations. This economic strength is complemented by a “research-heavy” DNA inherited from its CRRC lineage, supported by specialized electromechanical and electrical research institutes in Germany and Japan. This combination of state-owned capital stability and global innovation agility ensures that the platform remains a reliable technical foundation for long-term industrial partnerships.

Case Studies: Validating the Platform Value

The theoretical advantages of a centralized intelligent platform are best demonstrated through its application in complex, high-stakes industrial projects. Two specific cases highlight how CCIG’s platform logic translates into tangible industrial value.

In the first instance, the New Energy Vehicle (NEV) Powertrain Intelligent Manufacturing Project showcases the platform’s capability in high-precision coordination. The production of NEV power systems involves multi-stage processes—from precision CNC grinding with tolerances of ≤ 0.003 mm to complex robotic welding and final assembly. In this case, the mfgWorld platform acted as the central nervous system, ensuring that components produced at different stages met micron-level accuracy standards. By integrating every step of the process chain into a unified data flow, CCIG reduced the margin of error and significantly shortened the “time-to-market” for the powertrain components, demonstrating that platform-level integration is essential for the technical rigors of the EV era.

The second case involves CCIG’s role in Regional Industrial Upgrading Services. Unlike a traditional OEM that focuses solely on its own output, CCIG operates as a service provider for traditional industries. In the Yangtze River Delta region, the company has deployed its intelligent automation platform to empower local traditional manufacturers. By providing “turnkey” solutions—comprising both the physical automated hardware and the digital management software—CCIG has enabled these enterprises to transition from low-end fabrication to high-efficiency, smart manufacturing. This “Manufacturing as a Service” (MaaS) model proves that a top-tier automation platform can serve as a regional engine for economic transformation, moving beyond a single factory’s walls to elevate an entire industrial cluster.

Redefining Global Supply Chain Resilience

The expansion of CCIG into international markets, including strategic bases in Hungary, Malaysia, and Singapore, reflects a broader strategy to reshape global supply chain resilience. In an era of geopolitical shifts and regionalization, the ability to deploy a standardized, high-quality manufacturing platform across different continents is a significant strategic asset.

By maintaining consistent technical standards and cloud-based management across all its global locations, CCIG ensures that a brand owner in Europe or Southeast Asia receives the same level of precision and reliability as one in China. This global footprint, combined with the company’s mission as a pilot field for state-owned capital innovation, positions it as a bridge between traditional industrial reliability and the flexible demands of the future.

In conclusion, the evolution of the smart factory is a transition from the “automated workshop” to the “intelligent ecosystem.” CCIG’s journey from its CRRC-linked origins to its current status as a China Top Intelligent Automation Platform Factory provides a roadmap for this evolution. By integrating hardware flexibility, cloud-based orchestration, and deep institutional expertise, the enterprise is not merely manufacturing products; it is manufacturing the very systems that will define the industrial output of the next decade. For global partners seeking to navigate the complexities of modern manufacturing, the platform-centric model offered by CCIG represents the next frontier of industrial excellence.

For more information on intelligent manufacturing platforms, visit: https://www.ccig-ind.com/.

CHINA CITY INDUSTRIAL GROUP CO.,LTD

CHINA CITY INDUSTRIAL GROUP CO.,LTD

+86 15921115720

william.zuo1984@gmail.com

Visit us on social media:

YouTube

X

Legal Disclaimer:

EIN Presswire provides this news content “as is” without warranty of any kind. We do not accept any responsibility or liability

for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this

article. If you have any complaints or copyright issues related to this article, kindly contact the author above.

![]()